To avoid adhesion problems, the surface to be painted should generally always be dry, clean and free of grease. For problematic substrates, such as plastic, polystyrene or aluminium, the appropriate special primer should be used.

Runners in the coating can be caused by several reasons. To avoid these, always ensure that the spraying distance to the object is neither too short nor too far. The same spraying distance (15 - 25 cm) should always be maintained. In addition, the paint must not be applied too thickly. It is recommended to paint in several, even, thin layers, e.g. first horizontally and then vertically. Always start spraying outside the object to be painted to avoid paint runs.

White tarnishing" of the lacquer occurs, for example, when the humidity is too high. The "grey haze" can be polished out after the lacquer coat has dried thoroughly. The optimum application temperature is between 20 and 25°C, with low humidity. In this way, the effect can be avoided.

The varnish may peel if, for example, a primer with the plastic adhesion promoter was not applied when varnishing plastics, as the varnish has no adhesion to most plastics. In addition, cracks can occur if a highly pigmented varnish, e.g. a primer, is applied on top of a low-pigmented one, e.g. a topcoat.

The ideal paint build-up: 1. primer - 2. colour-giving basecoat or topcoat - 3. clearcoat. Furthermore, cracks can form in the paintwork if the paint build-up is carried out with different types of paint. For the complete paint build-up, always use the product series of one manufacturer to avoid incompatibilities.

Due to a too large spray distance, the paint does not run well on the surface. It dries in the air and settles on the surface as a spray mist. This can be avoided by maintaining a constant spraying distance (recommended 15 - 25 cm). In direct sunlight, "bubbles" can form which make the surface no longer shine. Therefore, paint in a sun-protected place, at an ideal processing temperature of approx. 20 - 25°C, with low humidity. In addition, painting in a place protected from the wind is recommended to preserve the gloss of the paint finish, which would be diminished by whirled-up dust.

Wrinkling refers to the so-called "pulling up" of the lacquer. If a synthetic resin varnish is overpainted with another type of varnish or with itself after drying, it will pull up or form wrinkles. Synthetic resin varnishes are oxidatively drying varnishes, i.e. they dry under the influence of atmospheric oxygen. It takes about 6 hours for the top layer of varnish to dry. After this time, the varnish should not be overpainted, because if the varnish is applied again, the lower layers of varnish will swell due to the renewed supply of solvents. Recommendation: Keep the same type of lacquer, e.g. NC lacquer on NC lacquer, for the lacquer build-up (primer, top coat, clear coat).

The so-called orange peel can be caused by a too large spray distance. The paint that has already dried in the air (spray mist) settles on the surface and no longer runs. Initially, the surface is only rough and partially matt. After a thicker application of lacquer, orange peel forms. This can be avoided with a constant coating distance of approx. 15 - 25 cm and ideal coating temperatures, between 20 and 25°C.

There are various reasons for this: The spray paint can may not have been shaken long enough. It should always be shaken thoroughly for 2 minutes from the audible stop of the mixing balls. This is necessary to mix the paint pigments. Another reason may be that the paint used does not cover well, which means that too little paint is applied. It can also be due to the lacquering itself. With metallic paints, the painting result depends on the spraying distance. If the spraying distance is too short, the colour will be too dark. If the spraying distance is too long, the final result will be too light. To avoid this, you should first test spray and check the colour shade, as well as maintain the ideal spraying distance (approx. 15 - 25 cm) and the same painting speed.

The spray paint can may not have been shaken properly, in which case it should be shaken again thoroughly for approx. 2 minutes. It is also possible that the spray can itself or the contents are too cold. In this case, you should slowly warm it up to the recommended processing temperature. Another reason could be dried product components in the riser tube or valve. In this case, turn the spray paint can upside down and spray twice so that the propellant dissolves the residues and transports them to the outside. In any case, make sure that the finger is placed correctly on the spray head so that no residue remains on the finger or can when the paint comes out.

An intermediate flash-off time, i.e. the waiting time between spray coats, must be observed between each paint application. Precoat one spray pass, in evenly thin coats, and apply a covering final coat after 3-5 minutes (varies depending on the product). This avoids overcoating and paint runs and the paint surface is evenly coated.

This can be recognised by the can weight, the audible stop of the mixing balls and in connection with the production date, which you will find encoded as a code on the can bottom, beaded rim or can end. The minimum shelf life of a 1K aerosol can is 5 years, the minimum shelf life of a 2K aerosol can is 3 years. For exact identification, please send us the product name and, if applicable, the article number and the code.

One reason could be that the fresh coating was applied at too low a temperature. At temperatures below 20°C, the lacquer dries more slowly, as drying, e.g. with NC/AC lacquers, takes place through evaporation of the solvent. Drying is temperature-dependent. The colder it is, the slower the solvent evaporates. It can also be a silicone resin varnish, which is mostly used for heat-resistant varnishes. These heat-resistant varnishes should only be used on cold objects and primer and clear varnishes should be avoided, as these are not heat-resistant in most cases. The finished painted objects, such as radiators, should be heated slowly.

The top layer of lacquer has dried and can be touched or transported. However, the surface is not yet mechanically loadable. A coating is loadable when it is completely dry. Overnight drying is optimal, i.e. 24 hours. These times vary depending on the spray paint product, so always check the information on the product label.

If the spray paint can is not empty, shake it up again until you hear the mixing balls again. It is possible that the valve has become clogged. In this case, wipe off any residue on the spray head nozzle, turn the spray paint can upside down and spray twice briefly.

A 1-coat lacquer means all lacquer systems that do not require overcoating with clear lacquer.

The two-coat paint system is preferably used in the automotive industry, e.g. for metallic colours. A base or topcoat is used as the colouring component, which must be overcoated with a 2-coat clearcoat. Although these paints are characterised by very good covering properties, they are not sufficiently weather-resistant without overcoating with a clearcoat.

1K means 1-component varnishes. These are basically all lacquers that are processed without the use of a hardener.

2K means 2-component lacquers. These are all lacquers that cure or dry by adding a hardener. In spray paint can technology, this means: Paint and hardener are combined in one spray paint can. The hardener is in a separate container that is released at the touch of a button and mixes with the paint. The 2-component system is particularly weather- and UV-resistant and ensures the highest product quality.

In a chemically drying varnish, drying takes place through a chemical reaction with the hardener. Once these 2-component lacquers are completely dry, they are particularly resistant and permanently weatherproof.

Physically drying varnishes are varnishes in which the drying process is based on the evaporation of the solvents. The varnish can be dissolved again with solvents.

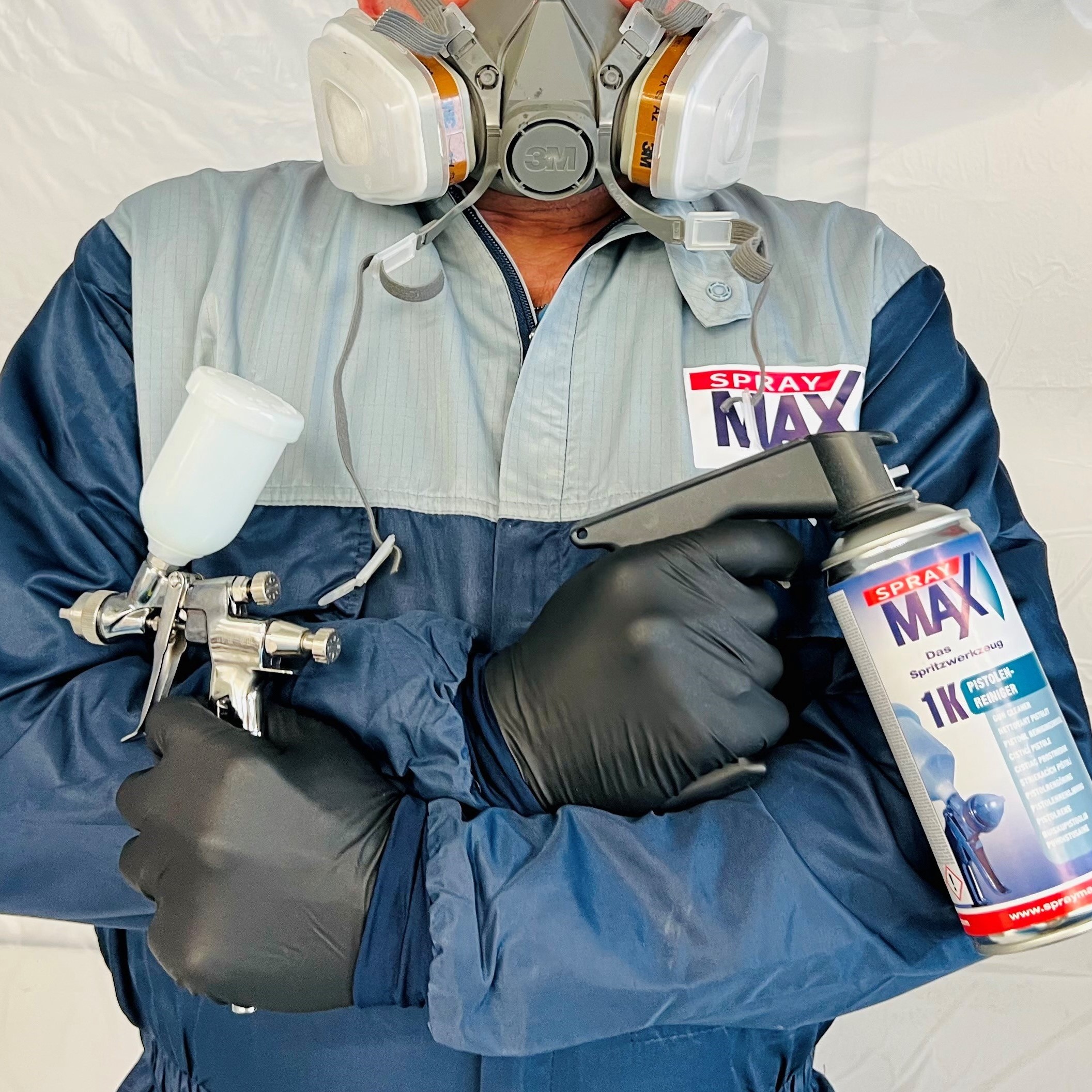

It is recommended to wear gloves, protective goggles and a protective mask (fine dust mask or paint mask) during paint preparation and painting.

The optimum painting temperature (ambient temperature) with aerosol cans is approx. 15-25°C and approx. 40-80 % relative humidity. At low temperatures, spray paint cans should be tempered somewhat. This is beneficial for the application behaviour.

If the mixing balls cannot be heard despite thorough shaking of the can, do not subject the can under no circumstances subject the can to mechanical stress, e.g. by knocking it open. In this case we recommend turn the can upside down and shake it thoroughly upside down.

The substrate to be painted or the object to be painted must be clean, dry and free of grease. Sand the surface to be painted and any existing old coats and (additionally) remove rust from metal.

The areas that are not to be painted or protected from spray mist are to be masked or covered over an appropriately large area.

Shake the spray paint can thoroughly for 2 - 3 minutes from the audible stop of the mixing balls so that the colour pigments of the paint mix well.

To avoid painting errors, test spray after shaking up the can and check the colour shade and compatibility with the substrate. Either on a cardboard box, a test object or an inconspicuous spot on the object to be painted.

The correct and consistent painting distance must be observed. This is approx. 15-25 cm, depending on the product. This is important to avoid coating errors such as runner formation. In addition, the information on the respective product label must be observed.

Drying times vary depending on the type of paint, object to be painted, substrate, temperature, humidity and film thickness. The drying times are differentiated between dust-dry, touch-dry and completely dry. The exact drying times can be found on the respective product label, technical data sheet or on the Internet.

The spray paint cans must be stored and transported upright, cool, dry and frost-free. The cans must be permanently protected from sunlight (never above 50°C), chemical and mechanical influences. The ideal storage location is in closed rooms, e.g. cellar, garage, workshop, etc. Safety instructions on the can and the legal regulations of the storage location must be observed.

A spray paint can should be used until no more paint comes out when the spray head is actuated or "no more hissing" can be heard. Only then is the can completely empty. Spray paint cans that have been emptied of residue are recycled via the collection of recyclable materials (yellow bin, yellow sack, containers for light packaging). Cans with contents are to be disposed of via hazardous waste. Removable plastic parts, such as caps and spray heads, are sent for plastic recycling via the collection of recyclable materials.

SprayMax FillClean products are, among other things, very precisely matched to the products to be filled by the formulations in contrast to "universal solutions". This adjustment achieves a higher accuracy, quality and ultimately also the paint level and appearance.

The unit mechanics require at least 7.5-8 bar. Lower pressure leads to malfunctions of the unit.

The difference lies in the can caps. With 1K FillClean products, the special can cap is also intended for use directly in the unit as an insert in the filling cylinder. This is not possible with 2K Fill In products, as the can cap carries the release button. 2K spray paint cans are therefore always Fill In versions. To fill 2K spray paint cans in the FillClean unit, use the separately available cap set including the adapter ring.